How to Properly Apply Thermal Paste: Complete, Practical Guide for Engineers (2026)

Any electronic component requires heat dissipation wherever heat is generated. Among all thermal interface materials (TIMs), thermal grease remains the preferred thermal material for thermal management solutions due to its low thermal resistance and excellent wettability. However, proper application is essential.

What Is Thermal Paste and How It Works

The Purpose of Thermal Paste

.webp)

Thermal paste—also called thermal compound, thermal grease, or TIM grease—fills microscopic air gaps between two mating surfaces such as a processor and a heatsink.

Its core function:

- Reduce thermal contact resistance

- Improve heat conduction efficiency

- Achieve stable temperature under dynamic loads

Why Bond-Line Thickness (BLT) Matters More Than Thermal ConductivityThermal resistance

- Material conductivity (W/m·K)

- Interface pressure

- BLT uniformity

Ideal BLT for most CPU/GPU applications: 20–60 μm

Ideal BLT for power modules: 50–100 μm

A thinner BLT reduces resistance—but only if uniform.

Preparing the Surface Before Applying Thermal Paste

Step 1 — Disassemble and Inspect

Check surfaces for:

- Scratches

- Oxidation

- Old paste residue

- Uneven machining marks

Minor scratches = okay.

Deep grooves = potential hotspot risk.

Step 2 — Clean with Approved Solvents

Use:

- 99% IPA

- Lint-free cloth

- ESD-safe wipes

Do NOT use:

- Tissue paper

- Alcohol with additives

- Water-based cleaners

Step 3 — Understand Pressure Zones

Important before applying paste:

- Center-loaded CPUs distribute pressure evenly

- Large IHS and power modules have asymmetric zones

- Uneven mounting torque leads to BLT gradients

Include torque guideline chart:

- Typical CPU mount torque: 0.4–0.6 Nm

- Larger modules: 1.0–1.5 Nm

How to Properly Apply Thermal Paste

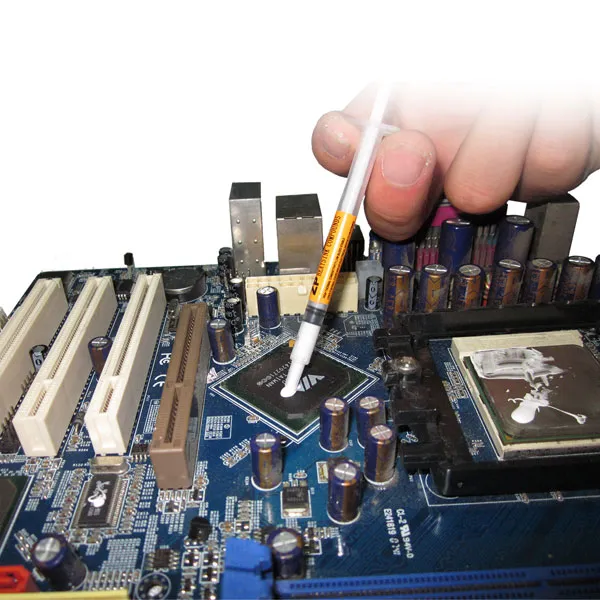

Method 1 — Pea-Dot Application

Best for:

- Intel/AMD desktop CPUs

- Most laptops

Why it works:

- Natural spreading from center

- Minimal risk of air pockets

- BLT tends to stabilize around 40–70 μm.

Method 2 — X-Pattern Application

Best for:

- Large IHS (Threadripper, server CPUs)

- Rougher surface finishes

Advantage:

- Consistent distribution across wide surfaces

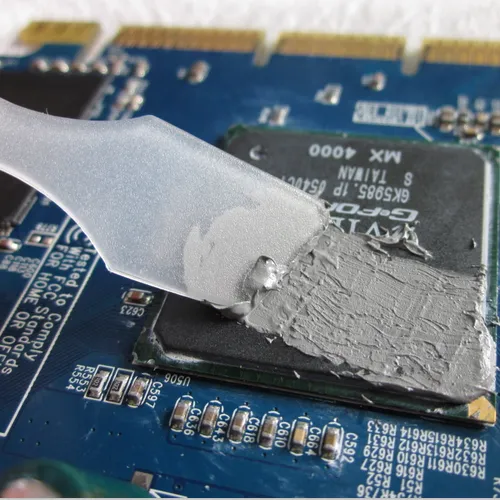

Method 3 — Spread Method

Best for:

- High-viscosity paste

- Uneven surfaces

- When precise BLT is needed for validation testing

Use a uniform 0.1 mm layer. Avoid trapped air bubbles.

Torque + BLT Correlation

Increasing torque → decreasing BLT

Decreasing BLT → lower thermal resistance

But over-tightening can warp PCB or IHS.

Testing & Troubleshooting Thermal Paste Performance

Post-Installation Verification

Measure:

- CPU package temperature

- ΔT from idle to full load

- Temperature stability over 10–15 minutes

Pass criteria:

- ΔT < 40°C under full load (consumer CPUs)

- ΔT < 20°C for power modules (depends on load)

Signs of Incorrect Application

- Spikes during load → uneven spread

- Gradual temperature climb → curing or pump-out

- One core significantly hotter → BLT inconsistency

Conducting a Re-Application Test

1.Remove heatsink

2.Inspect pattern

3.Re-apply with alternative method

4.Compare ΔT difference

Typical improvement after correct re-application: 4–10°C.

Common Myths and Mistakes

Myth 1 — “More paste = better cooling”

Fact: Excess causes pumping, overflow, and higher BLT.

Myth 2 — “You must reapply every few months”

Modern thermal paste lasts 3–7 years when used properly.

Myth 3 — “Liquid metal is always better”

Risk:

- Conductive

- Corrodes aluminum

- Requires skilled application

Mistakes Engineers Still Make

- Using paste to “fill gaps” (use pads instead)

- Applying paste on dirty surfaces

- Ignoring torque consistency

- Mixing different pastes together

FAQ — People Also Ask

-

How much thermal paste should I apply?

Usually a pea-sized dot (0.1–0.2 ml). -

Do I need to replace thermal paste every year?

Not necessary—most pastes last several years unless thermal cycling is extreme. -

Can thermal paste damage CPUs?

Only electrically conductive pastes (e.g., liquid metal) pose risk. -

Does thermal paste improve FPS?

Indirectly—lower temperature enables stable boost clocks. -

What if I applied too much paste?

Remove and redo. More paste increases thermal resistance.

Correct thermal paste application remains one of the most influential factors in achieving stable cooling performance. With the right preparation, method, and verification steps, engineers and PC builders can significantly lower interface resistance, stabilize operating temperatures, and maximize long-term reliability.

If you need engineering guidance, BLT validation, or help selecting the right thermal compound for your application, contact our thermal engineering team for a free consultation.

English

English

usheenthermal

usheenthermal