Synthetic Graphite Sheets: Maximizing Thermal Diffusion in Next-Gen Electronics

In the development of every electronic product, heat dissipation remains an unavoidable limiting factor. Heat issues can lead to decreased performance, shorter battery life, and poor stability.Synthetic graphite sheets, with their unique advantages and superior performance, have become the preferred thermal management material for engineers. This article will delve into the characteristics of synthetic graphite sheets and their crucial role in applications, helping you choose a thermal management solution that truly works in production.

Understanding Synthetic Graphite Sheets: Material Properties and Thermal Performance

Material Composition and Structure

- Synthetic graphite sheets are manufactured by graphitizing carbon precursors and compressing exfoliated graphite into thin, highly crystalline lamina. Typical sheet thicknesses are 10–200 µm.

- Result: very high in-plane conductivity (k_xy) and low through-plane (k_z), producing strong anisotropy.

Thermal Conductivity & Heat Dissipation Mechanisms

- Heat travels mainly by phonons in the sp² lattice. In-plane scattering is minimal, so lateral spreading is efficient.

- Practical note: PGS excels at redistributing a hotspot’s power over a larger area; it is not a primary through-plane conductor (copper still outperforms PGS in through-plane conduction).

Advantages over Traditional Materials

- Ultra-thin, light: same spreading with less mass than copper.

- High in-plane k per gram and small z-profile enable slimmer designs.

- Caveats: conductive electrically (requires dielectric laminate), limited bending fatigue at very thin gauges.

The Science of Anisotropy: Why Synthetic Graphite Sheets Outperform Traditional Materials

Anisotropic Thermal Conductivity Explained

- Define anisotropy ratio = k_xy / k_z. For quality PGS this can be >100×, meaning heat flows far more easily sideways than through the stack.

How Anisotropy Enables Superior Heat Spreading

- By increasing the effective spreading radius, PGS reduces local heat flux density on a hot spot and lowers junction temperature without adding height.

- Design heuristic: make PGS lateral dimension ≈ 3–5× the hotspot dimension to get meaningful ΔT reductions.

Competitive Analysis: Synthetic Graphite Sheets versus Alternative Thermal Management Technologies

Comparison with Thermal Interface Materials (TIMs)

- TIMs (paste/pads/PCMs) fill interface gaps and reduce contact resistance but do little lateral spreading. PGS supplements TIMs: TIM fills gaps; PGS spreads the heat.

Comparison with Active Cooling (Vapor Chambers & Heat Pipes)

- Vapor chambers/heat pipes are excellent where vertical transfer to remote sinks is feasible; PGS is ideal when z-height is constrained and lateral spreading onto an existing chassis/frame is needed. In many designs, PGS + vapor chamber provides the best tradeoff.

Cost-Benefit and Lifecycle Analysis

- Consider TCO: unit material cost + assembly complexity + reliability gain (reduced throttling/returns). PGS often enables smaller mechanical solutions, saving BOM cost downstream.

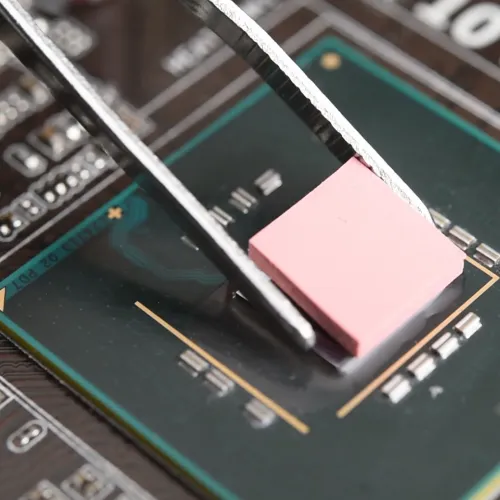

Optimizing Thermal Interface Performance with Synthetic Graphite Sheets

Surface Preparation and Micro-Conformability

- Cleanliness and surface flatness matter; recommended: 99% IPA wipe, <5 µm particulate spec in lamination area.

- PGS is flat but not conformal—use a thin TIM layer or compliant adhesive to bridge micro-gaps at contact interfaces.

Integration with Lamination and Insulation Layers

- Dielectric films (PET/PI) are typically laminated for electrical isolation; expect added through-plane resistance. Minimize film thickness and use high-k dielectric if possible.

Advanced Applications: From Foldable Displays to EV Battery Systems

Thermal Management in Foldable Displays

- Requirements: ultra-thin, high bending cycles. Use thicker PGS grades or laminated stacks to improve flex fatigue life. Request bend-cycle data (e.g., 100k cycles at radius X) from suppliers.

Thermal Management in Electric Vehicle (EV) Battery Systems

- PGS can be used at module level to equalize surface temperatures and reduce local hotspots; consider scale and cost—often combined with PCM or cold plates.

5G Devices and Data Center Hardware

- 5G mmWave front-ends and high-density servers benefit from lateral spreading where z-height is limited; PGS reduces local hot-spot intensity and supports higher sustained power.

Frequently Asked Questions

Q: Are synthetic graphite sheets electrically conductive?A: Yes — they require dielectric films or edge sealing for PCB use.

Q: Can PGS replace copper entirely?

A: No; PGS is a lateral spreader and copper remains superior for through-plane conduction to a remote sink.

Q: What test data should I request from suppliers?

A: k_xy & k_z at specified thickness, test method, R″ at your BLT, bend-cycle data for foldables, and adhesion/lamination specs.

Synthetic Graphite Sheets deliver a unique combination of extreme in-plane conductivity and ultra-thin form factor that solves lateral heat-spreading challenges in next-gen electronics. To harness their benefits, convert supplier k values into R″ for your stack, control lamination and adhesive layers, and qualify with ASTM-style tests and application-specific reliability cycles. Contact us our thermal engineering team for a stack evaluation and pilot test.

English

English

usheenthermal

usheenthermal

.webp)