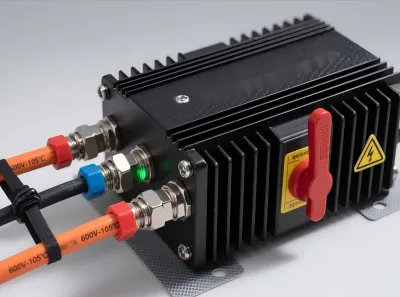

Non-Silicone Formula: Avoiding the Pitfalls of Traditional Materials

While traditional silicone-based thermal materials are widely used, the issue of siloxane volatilization remains an industry-wide problem. Volatile substances can accumulate on metal contacts and circuit boards inside the BDU over time, increasing contact resistance and causing metal corrosion, leading to poor contact, insulation degradation, and other failures that severely threaten BDU reliability. Non-silicone thermal gel takes a different approach, using modified resin as the base material combined with high-efficiency thermal fillers such as nano-sized alumina and boron nitride. By precisely adjusting the type, particle size, and content of fillers, it constructs an efficient three-dimensional thermal network, achieving flexible gradient coverage in the 1-10W/m·K thermal conductivity range. This meets the heat dissipation needs of low-power BDUs in small passenger vehicles while also addressing the demanding conditions of high-power BDUs in commercial vehicles.

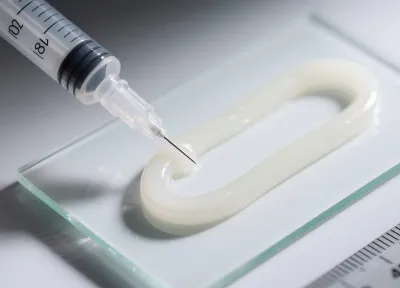

Threefold Capabilities for Heat Dissipation: Close Contact, Fast Transfer, and Leak Prevention

The compact internal structure of BDUs creates microscopic gaps and steps between power components and heat dissipation shells, which can become heat "traps." The 1-10W/m·K non-silicone thermal gel features unique low-modulus properties, allowing it to fully fill all gaps like a "liquid cushion" under assembly pressure. This reduces interfacial thermal resistance to below 0.05°C·cm²/W, enabling heat to transfer along the shortest path to the heat dissipation shell. Authoritative tests show that BDUs using 3W/m·K non-silicone gel exhibit a 12°C reduction in core component temperature after continuous 300A current impact for 1 hour, with a 40% slower contact temperature rise rate compared to traditional thermal pad solutions, fundamentally eliminating "local overheating."Insulation and flame resistance are critical safeguards for BDU operation. This material boasts a volume resistivity exceeding 10¹⁴Ω·cm, forming a robust "insulation armor" to prevent current leakage. It has also passed UL94 V0 flame resistance certification, ensuring it does not support combustion even under extreme high-temperature conditions, enhancing safety redundancy in complex environments. More importantly, it maintains stable performance across a wide temperature range of -40°C to 150°C, providing reliable protection for BDUs in both extreme cold and scorching heat.

Optimized for Mass Production: Visible Cost Reduction and Efficiency Gains

For automakers, high-quality materials must seamlessly integrate into mass production processes. The 1-10W/m·K non-silicone thermal gel supports high-precision automated dispensing, with accuracy controlled within ±0.05mm. It ensures uniform application even in the complex cavity structures of BDUs, guaranteeing full heat dissipation coverage. Compared to traditional thermal pads, it eliminates cutting and fitting steps, reducing human error. After curing, it exhibits no sagging or volatile emissions, complying with automotive VOCs environmental standards. Production data from a leading automaker shows that after switching to this material, the BDU thermal management process saw a 25% increase in production cycle time, a reduction in defect rate from 0.8‰ to 0.2‰, and a 12% decrease in per-unit manufacturing costs, achieving optimization in quality, efficiency, and cost.

English

English

usheenthermal

usheenthermal