Cleverly Eliminating Thermal Resistance Barriers: Graphene Structure is the Foundation

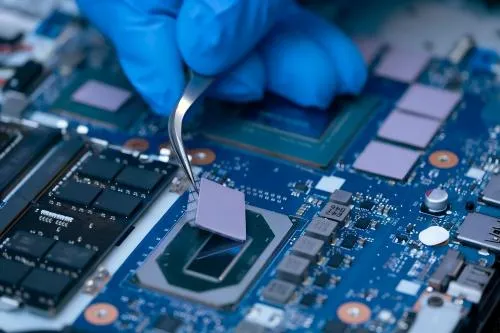

The root cause of thermal challenges in domain controllers is “thermal resistance barriers” that lead to heat accumulation. Heat generated by chips passes through multiple stages, and the thermal resistance at each stage reduces efficiency. Conventional silicone pads have insufficient thermal conductivity and high thermal resistance, making it difficult to establish efficient heat transfer paths. Graphene thermal pads break through with their material structure: graphene’s in-plane thermal conductivity exceeds 5000 W/(m·K). Through directional alignment, a “thermal conduction network” is formed, not only achieving a thermal conductivity of 70 W/(m·K) but also keeping interfacial thermal resistance below 0.1°C·in²/W. In application, it fills microscopic gaps between chips and heat sinks, eliminating high-resistance air layers, enabling heat to transfer to the heat sink with “low resistance,” fundamentally resolving local overheating.Excellent Compatibility with Domain Controllers: Multi-Dimensional Properties Meet Requirements

Domain controllers must withstand vibration and shock, operate in a wide temperature range of -40°C to 125°C, and have compact layouts, placing high demands on thermal materials. Graphene thermal pads are precisely designed to meet these needs: their flexibility and compressibility allow stable thermal performance even at 20%-30% compression, adapting to chip height variations and preventing rigid damage; the aging-resistant silicone base material experiences less than 5% thermal decay after 1000 hours of high-low temperature cycling, contains no harmful substances, and complies with automotive electronics standards; they can be precisely cut according to PCB layouts, with a minimum thickness of 0.2 mm, enabling “thin-profile heat dissipation” and supporting the miniaturization of domain controllers. These “customizable + durable” features allow them to integrate perfectly into domain controller designs, going beyond being just a “thermal accessory.”

Tangible Performance Gains: Data Supports High Value

The cooling effect is reflected in the operational performance and service life of domain controllers. In a comparative test conducted by an automaker on domain controllers, using graphene thermal pads and traditional silicone pads respectively: when the domain controller operated at full load of 45W, the junction temperature of chips with graphene pads was only 82°C, a full 18°C lower than with traditional pads; during a continuous 1000-hour full-load aging test, the domain controllers with graphene pads showed no performance fluctuation, while the group with traditional pads experienced two functional reboots due to overheating.This improvement not only allows the MCU to operate stably at rated frequency, avoiding frequency reduction triggered by overheating, and ensuring control accuracy and response speed of the domain controller; on the other hand, according to the general lifespan model of electronic components, every 10°C reduction in chip junction temperature can extend service life by 2-3 times, effectively doubling the lifespan of domain controllers and significantly reducing maintenance costs caused by hardware aging.

Leading Industry Trends: Technological Upgrade Drives Transformation

With the advancement of vehicle electrification and intelligence, domain controllers will become more integrated, potentially incorporating lidar control modules in the future, with power density possibly exceeding 100W, making heat dissipation requirements even more stringent. Graphene thermal pads at 70 W/m·K not only solve current challenges but also point the way for upgrades: optimizing the graphene doping ratio may enable future thermal conductivity to exceed 100 W/(m·K); combining with phase change materials could develop composite solutions for “active temperature control + passive heat conduction.” This iterative potential makes them not just a “solution,” but a “catalyst” for the development of domain controllers toward higher integration and performance, injecting new momentum into automotive electronics.Under the wave of automotive intelligence, only by solving the heat dissipation of core components can domain controllers fully play their role as the “central nervous system,” delivering a safer and more stable driving experience for users——this is the value of such professional thermal solutions. Sheen’s technological exploration and product implementation in this field also provide practical and effective thermal support for the industry.

English

English

usheenthermal

usheenthermal