Lightweight Revolution: From "Weight-Bearing Heat Dissipation" to "Efficient Protection"

The essence of range anxiety in NEVs is the trade-off between "weight and energy consumption". Data shows that for every 100kg increase in vehicle weight, energy consumption per 100 kilometers rises by 8-10 kWh. In traditional cooling systems, a single set of metal heat sinks can weigh 3-5kg, and after covering the battery pack with high-specific-gravity silicone pads (density 1.5-2.0g/cm³), the additional weight exceeds 2kg. Through "hollow microsphere composite technology", low-density thermal gel controls its density to 0.8-1.2g/cm³, merely 1/7th that of aluminum alloy and 60% that of traditional silicone pads.In an application for a pure electric platform of an automaker, replacing traditional thermal pads in the battery pack with this gel reduced the weight of the single-vehicle thermal system by 1.2kg. Combined with the vehicle's lightweight design, energy consumption per 100 kilometers decreased by 0.6 kWh. Based on an annual mileage of 20,000 km, this saves approximately 480 yuan in electricity costs per year (calculated at 0.8 yuan/kWh). More crucially, its flexible nature allows it to adapt to the curved structure of the battery pack, avoiding contact gaps caused by vibration in metal parts, fundamentally resolving the "weight - heat dissipation" contradiction.

Thermal Conductivity Precision: Hitting the "Demand Bullseye" for Core Components

The thermal conductivity requirements of different core components in NEVs vary significantly: power battery packs require thermal materials to achieve uniform temperature control (temperature difference must be ≤5°C) to avoid local overheating leading to thermal runaway; motor controllers (IGBT modules) require thermal materials to quickly conduct heat away due to high instantaneous power density (junction temperature must be ≤125°C); onboard chargers require thermal materials to balance cooling efficiency and cost.Low-density thermal gel utilizes a composite filler system of "nano-aluminum nitride + micro-aluminum oxide" to achieve precise adjustment of the thermal conductivity coefficient. Simultaneously, surface modification technology reduces the interfacial thermal resistance between the filler and the matrix, resulting in an actual thermal efficiency more than 30% higher than ordinary silicone pads of the same coefficient. Within the operating temperature range of -40°C to 150°C, its thermal conductivity attenuation rate is ≤5%, far lower than the industry average standard of 10%. Data from an automaker's extreme cold winter test showed that a battery pack equipped with this gel charged 15% faster at low temperatures (-10°C) compared to traditional solutions, with an 8% improvement in range stability, precisely thanks to its precisely matched thermal performance.

Process Adaptation: Solving the "Space Dilemma" of High-Density Assembly

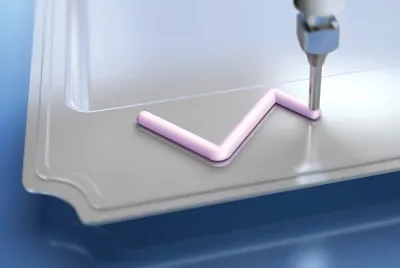

As NEVs upgrade towards "integration", the volumetric density of battery packs and e-drive systems continues to increase, with component gaps shrinking from the traditional 0.5-1mm to 0.1-0.3mm. Ordinary thermal materials struggle to meet demands due to poor flowability and low conformability. Thermal gel possesses excellent thixotropy and flowability. Under low-pressure dispensing processes (0.1MPa), it can achieve a gap fill rate of over 98%, even penetrating into tiny gaps of 0.05mm, forming complete thermal pathways.Its curing shrinkage rate is ≤1%, much lower than traditional epoxy thermal adhesives (3-5%), avoiding cooling gaps caused by shrinkage. In an application on an automaker's battery pack production line, using automated dispensing processes for this gel improved assembly efficiency by 20% compared to traditional cut silicone pads, reduced the defect rate from 3% to 0.5%, and saved nearly one million yuan in rework costs annually. Furthermore, its vibration resistance (no performance degradation at 10-2000Hz frequencies) adapts to the complex conditions during vehicle operation, ensuring long-term thermal stability.

Safety Bottom Line: Building a "Protective Barrier" for the Full Lifecycle

Heat dissipation failure is a significant cause of safety incidents in NEVs. Industry statistics indicate that approximately 30% of power battery safety incidents are related to poor heat dissipation. Low-density thermal gel inherently builds safety protection from its material properties: it is UL94 V-0 flame retardant certified, forming a dense char layer upon fire exposure without burning or dripping; its volume resistivity is ≥10¹⁵ Ω·cm, far exceeding the insulation performance requirements of the GB/T 1408.1 standard, effectively preventing component short circuits; it also possesses excellent aging resistance, showing no cracking or delamination after 1000 thermal cycles (-40°C to 125°C) and 500 hours of damp heat aging (85°C/85% RH), fully meeting the 10-year / 200,000-km service life requirement for NEVs.In the context of the gradual popularization of 800V high-voltage platforms, this gel can also be formulated to achieve high voltage resistance (≥30kV/mm), providing safety assurance for cooling high-voltage components. It becomes a key support for upgrading NEV heat dissipation from "basic cooling" to "safe cooling".

From solving user range anxiety, to helping automakers reduce costs and improve efficiency, to ensuring driving safety, 3-6W/m·K low-density thermal gel is not just a thermal material; it is a crucial "technology puzzle piece" for the electrification upgrade of new energy vehicles. Companies like Sheen, which have deep expertise in the field of thermal materials, are also continuously following up on new demands brought by solid-state batteries and autonomous driving, promoting the iteration of such materials in scenarios like battery thermal management and onboard chip cooling.

English

English

usheenthermal

usheenthermal