Thermal Gap Filler and Thermal Gap Pads — How to Choose the Right Solution

In modern high-power electronics, teams commonly use two methods to dissipate heat: thermal gap fillers (dispensing, phase change materials, curing adhesives) and thermal gap pads (pre-formed compressible sheets/die-cut parts).This article explains the differences between these two methods and provides a comprehensive comparison of these two key thermally interface materials (TIMs) across six engineering areas: physical properties, assembly costs, and long-term reliability, ensuring you choose the right solution for your specific application.

What are thermal gap filler and thermal gap pads?

Understanding the fundamental difference in form and function is the first step toward effective selection..webp)

A thermal gap filler is a material applied to fill irregular or variable gaps between mating surfaces. Formats include:

- Dispensed gels (non-curing or semi-curing); applied with a syringe or robot nozzle.

- Curing gap fillers (epoxy/polyurethane) that provide a permanent thermally conductive path and sometimes structural bonding.

- Phase-change materials (PCMs) that are solid at room temperature for clean handling but melt at operating temperature (~50–65°C) to wet the contact surfaces.

- When used: irregular geometries, pockets, or assemblies where a conformal thermal interface is required.

- Application methods: manual bead/syringe, robotic dispense, or pre-metered cartridges. Some fillers cure in-line; PCMs reach their low R″ only after first power-up.

.webp)

- Nominal thickness: commonly 0.3–5.0 mm.

- Compression behavior: designed to compress a specified percent (30–50%) under clamp force.

- Installation: peel-and-place, pick-and-place from tape-and-reel, or manual placement.

- When used: predictable gaps, high-volume lines, assemblies requiring electrical insulation or easy rework.

Quick comparison table — thermal gap filler and thermal gap pads

| Feature | Thermal Gap Filler | Thermal Gap Pads |

| Form | Liquid/gel/PCM | Solid sheet / die-cut |

| Typical BLT achievable | Thin in pockets after flow | Nominal thickness compresses to BLT |

| Reworkability | Often permanent (depends) | Usually reworkable |

| Best for | Irregular geometry, pockets, thin BLT | Repeatable gaps, fast assembly, insulation |

| Cleanliness risk | Potential outgassing or residue | Lower (unless oil-bleed) |

Thermal Properties and Physical Characteristics — compare thermal gap filler and thermal gap pads

The perceived difference in raw thermal conductivity (W/mK) is often irrelevant; actual performance is determined by the system's Thermal Impedance (Rth).

Surface Wetting and Thermal Impedance (Rth)

The most significant factor affecting Rth is Contact Resistance (Rcontact), caused by microscopic air gaps at the interface.- Gap Filler Advantage: Because the material is semi-liquid, it achieves near-perfect surface wetting under minimal pressure, pushing air out and virtually eliminating Rcontact.

- Gap Pad Disadvantage: A pad relies on being compressed (typically 30-50% of its thickness) to conform to surface roughness. If compression is uneven or insufficient, microscopic air gaps remain, increasing Rth.

Compression Stress and Component Safety

This is a critical mechanical distinction.- Gap Filler Advantage: Exerts near-zero stress on components, making it the safest choice for systems with fragile BGA (Ball Grid Array) packages and delicate ICs.

- Gap Pad Disadvantage: The pad's inherent Shore Hardness translates directly to force. Excessive pressure to achieve conformity can cause PCB warping or induce failure in the solder joints.

Achieving Optimal Bond Line Thickness (BLT)

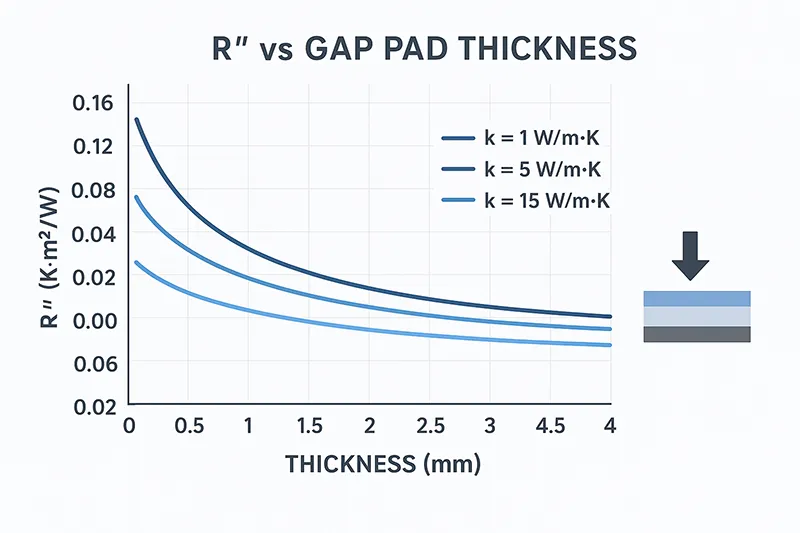

The total heat resistance is directly proportional to the thickness (Rth & BLT).

-

Gap Filler Advantage: Automated dispensing allows for precise control of material volume, resulting in the minimum, consistent BLT possible for the gap.

-

Gap Pad Disadvantage: The pad's thickness is fixed (e.g.,1.0mm). Even if the gap could technically be filled by 0.8mm, the excess material simply increases the thermal path length.

When to Choose Thermal Gap Filler or Thermal Gap Pads?

The selection framework is driven by manufacturing economics and component protection.

From an application perspective

Choose thermal gap filler when:

- The gometry includes pockets or irregular surfaces that pads cannot reliably contact.

- You want the clean handling of a PCM with paste-like final performance.

- You need the thinnest possible BLT in localized areas to control hotspot temperatures.

Choose thermal gap pads when:

-

Gaps are predictable and repeatable across assemblies.

-

Electrical insulation is required (pads can be ceramic-filled and rated for kV/mm).

-

Reworkability and field serviceability matter.

Example: EV battery module — large predictable gaps plus need for dielectric isolation → typically gap pads. Small telecom RF module with irregular cavity and hotspot → dispensed PCM or gel may perform better.

From an assembly speed and automation perspective

- High-volume, fastest throughput: die-cut thermal gap pads on tape are fastest (pick-and-place).

- Flexible line / medium volume: dispensed fillers give layout flexibility but increase cycle time (cure or tack time) and require dispense maintenance.

- Automation notes: dispensing needs nozzle cleaning routines and in-process inspection to avoid voids; pads need accurate placement and verification (vision).

From a cost perspective (material waste)

- Material cost per part: pads usually incur higher material mass but lower labor per unit; dispensed materials can be economical in material usage but require capital for dispensers and maintenance.

- Waste: dispense overshoot and purge cycles create waste; die-cut pads reduce per-unit waste but require inventory commitment.

- Actionable tip: calculate total cost of ownership (TCO) — material + assembly labor + predicted warranty/field return cost — not just per-gram cost.

From a reworkability perspective

- Pads: removable, excellent for products that may be serviced or upgraded.

- Fillers (curing/adhesive): can be permanent; removal risks damage. Use fillers only if rework is unlikely or you’re comfortable with rework procedures. PCMs are more amenable to rework than fully cured adhesives because they return to solid at room temp, but they may still stick.

From a part tolerance and clearance variation perspective

- High variation: fillers conform better; choose PCM or gel for variable gaps.

- Low variation: pads give reliable, repeatable compression and predictable thermal performance.

Decision-making process and quick rules

- Gap < 0.2 mm → favor paste/PCM.

- Gap 0.2–0.5 mm → dispensed filler or thin pad depending on geometry and automation.

- Gap > 0.5 mm → pad usually best.

- Need fast assembly & rework → pad.

- Need conformity and lowest local BLT → filler/PCM.

Frequently Asked Questions — thermal gap filler and thermal gap pads

Q1 — What’s the key difference between a thermal gap filler and a thermal gap pad?

A: Gap fillers are dispensed liquids/gels/PCMs that conform to geometry; gap pads are preformed compressible sheets. Fillers are better for pockets and irregular shapes; pads are faster to place and easier to rework.

Q2 — Which gives better thermal performance?

A: It depends — compute R″ = t / k at your expected BLT. A thin dispensed filler or PCM that wets the interface usually yields lower R″ than a thick pad. But a well-compressed high-k pad can be competitive.

Q3 — Are dispensed gap fillers reworkable?

A: Many curing fillers are permanent and complicate rework. PCMs are easier to handle but still may require careful removal. Prefer pads for serviceable products.

Q4 — How do I stop pump-out or oil bleed?

A: Use low-mobility gels, PCMs, cured formulations, silicone-free materials, perimeter seals, or mechanical retention. Validate in thermal cycle tests.

Q5 — Can I stack pads to reach a large gap?

A: Not recommended — interfaces between stacked pads add contact resistance and compress unpredictably. Order a correct nominal thickness or use a liquid filler.

Q6 — What tests should I require from suppliers?

A: Through-plane k @ thickness & pressure (ASTM D5470 if possible), R″ at your BLT, compression set % at temperature, dielectric strength, TML/CVCM for optics, and pilot reliability runs (TC, 85/85).

The choice between thermal gap pads and thermal gap filler is a strategic balance linking design requirements to factory capabilities. Pads are perfect for low-volume, high-rework applications. Fillers are the definitive choice for high-volume, automated production where low assembly stress and superior thermal performance control are critical.

At Sheen Technology, we offer comprehensive thermal interface solutions designed to meet the most demanding requirements. Visit our website or contact our technical support team to learn how Sheen Technology's thermal interface materials can enhance your product's thermal management capabilities.

English

English

usheenthermal

usheenthermal