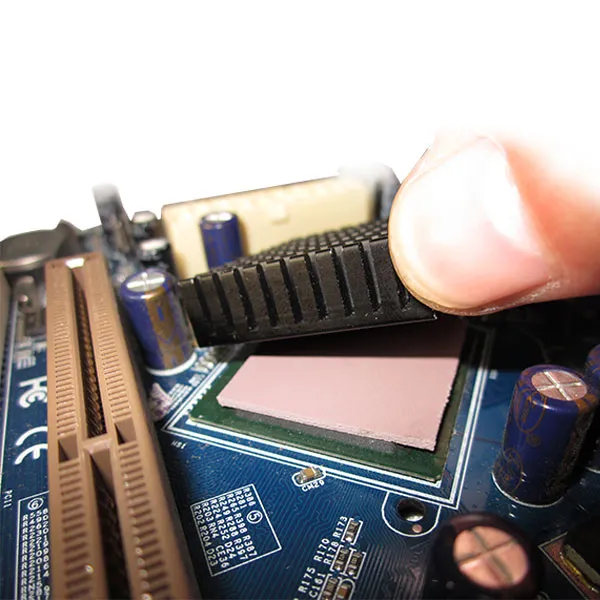

What Is a Thermal Gap Pad?

In the field of thermal management, air is the main enemy. Air has a thermal conductivity of only approximately 0.026 W/mK, significantly hindering heat dissipation efficiency. Choosing the right thermal gap pad can replace this air, allowing heat to be predictably transferred from the device to the heat sink.This is where thermal gap pads come into play. For reliability engineers, choosing the right gap pad is not just about lowering temperature; it's about ensuring your product functions correctly in real-world applications, rather than being returned for repair.

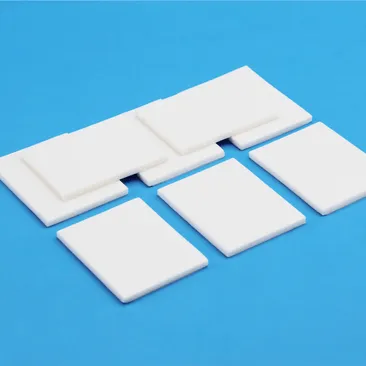

Thermal Gap Pad Types & Materials

Not all thermal interface materials perform the same. The chemical composition of the pad determines its long-term reliability and suitability for sensitive environments.

.webp)

Characteristics: The vast majority of thermal interface pads are silicone-based. The silicone polymer backbone offers naturally high temperature stability (-50-200℃) and low modulus (flexibility).

Applications: General electronic products, automotive power modules, and outdoor telecommunications equipment. Components requiring electrical insulation and quick, adhesive assembly. Advantages/Disadvantages: Easy to apply, not highly sensitive to flatness requirements; in narrow gaps, its thermal resistance R″ is higher than thin thermal paste; prone to compression deformation over time. Silicone naturally contains low molecular weight (LMW) siloxanes. Over time, these substances can migrate (outgas) from the pad.

.webp)

Main advantages: Excellent lateral (in-plane) thermal conductivity; manufacturer-claimed thermal conductivity is typically 15–45 W/m·K.

Important considerations: Many carbon materials are highly anisotropic – in-plane thermal conductivity can be high, while vertical (Z-axis) thermal conductivity is lower.

Handling: May be brittle; requires careful cutting and edge handling.

Reasons for use: In optical sensors, automotive cameras (ADAS), and hard drives, migrating silicone oil can fog lenses or insulate electrical contacts. Silicone-free pads enable zero outgassing.

Suitable applications: Applications involving optical paths or requiring high-cleanliness electronics.

Required specifications: TML and CVCM conforming to ASTM E595 standards.

Trade-offs: They are generally harder than silicone pads and have lower high-temperature limits (approximately 130°C).

-

Reinforced Polymer Pads

Ceramic filled (Al₂O₃, BN, AIN): Electrically insulating, temperature resistant up to approximately 150–200°C, moderate thermal conductivity (1–7 W/m·K).

Metal filled: Higher thermal conductivity (can exceed 10 (W/m·K), but it is electrically conductive – therefore, it is only suitable for applications where insulation measures have been taken.

The Physics Behind Thermal Gap Pads

To select the right pad, you must understand the difference between material properties and system performance.

From k to R″ — why thickness (BLT) matters

Thermal conductivity k (W/m·K) is useful but incomplete. For through-thickness heat flow the meaningful metric is thermal impedance per unit area (R″):R′′=t/k

where t is pad thickness (m). The temperature rise across the pad for heat flux q (W/m²):

ΔT=q⋅R′′

Worked example (practical):Hot-spot flux q = 100,000 W/m² (100 kW/m²).

- Paste-like thin TIM: t = 0.05 mm (0.00005 m), k = 5 W/m·K → R″ = 0.00005 / 5 = 1.0×10⁻⁵ K·m²/W → ΔT ≈ 1.0°C.

- Pad: t = 0.5 mm (0.0005 m), k = 6 W/m·K → R″ ≈ 8.33×10⁻⁵ K·m²/W → ΔT ≈ 8.33°C.

Takeaway: thick pads — even at similar k — can produce several °C higher interface temps because BLT dominates.

Assembly factors that change real performance

- Compression / clamp force: compresses pad, reduces t and R″. Specify k measured at your expected compression percent.

- Surface flatness/roughness: microvoids increase contact resistance. Controlled finishes and flatness specs matter.

- Temperature dependence: some materials’ k varies with temperature — request k vs T if operating range is wide.

How to Select the Right Thermal Gap Pad

Selection is a balance between thermal performance and mechanical stress management.-

Step 1 — Measure your gap and set BLT target

Target BLT ≈ nominal gap × (1 − desired compression).

Example: nominal gap 0.8 mm with 40% compression → select 1.3 mm nominal pad.

Warning: Do not over-compress (>50%). Excessive pressure changes the material density and can bend the PCB.

| Nominal gap (mm) | Target compression (%) | Nominal pad thickness to order (mm) | Typical pad type |

| < 0.10 | 30–40% | 0.14 – 0.17 | Thin PCM / high-fill silicone sheet |

| 0.10 – 0.20 | 30–45% | 0.14 – 0.36 | Thin silicone pad / PCM |

| 0.20 – 0.50 | 30–50% | 0.29 – 1.00 | Silicone pad / gel dispensed gap filler |

| 0.50 – 1.00 | 30–50% | 0.71 – 2.00 | Compression silicone pad / ceramic-filled pad |

| 1.00 – 2.00 | 30–50% | 1.43 – 4.00 | Thick gap filler pad / conformal pad |

| > 2.00 | 20–40% | Custom | Custom |

-

Step 2 — Define performance and safety specs

R″ at target BLT

Dielectric strength (kV/mm) and volume resistivity (Ω·cm)

Compression set at elevated temp, Tg, flammability (UL94)

VOC / outgassing (if optical sensors present)

-

Step 3 — Manufacturing & assembly fit

For low-volume or prototype use cut-to-fit sheets.

Consider adhesive backing for retention if parts move before final fastening.

-

Step 4 — Pilot & qualification

Acceptance example: ΔR″ change <10% after 500 cycles.

Key Applications for Thermal Gap Pads

-

Electric Vehicle (EV) Battery Modules

Material selection: Silicone pads with high dielectric strength, or carbon fiber thermal sheets for lateral thermal balancing.

-

LED Lighting and Optical Modules

Material selection: Silicone-free thermal pads for optical applications; phase change materials (PCM) for applications requiring high cleanliness and low thermal resistance.

-

5G/Telecommunications and Outdoor Electronics

Material selection: Weather-resistant thermal silicone pads.

-

Consumer Electronics and Laptops

Material selection: Thin, silicone-free thermal pads or silicone-free phase change materials for compact designs.

Reliability, Failure Modes & Testing for Thermal Gap Pads

Common Failure Modes

- Compression Set: The pad height decreases over time, causing the gap to reappear. The pad may lose contact with electronic components during the cooling phase, leading to a sharp increase in thermal resistance.

- Oil Bleeding/Outgassing: Low-quality silicone materials can bleed oil, attracting dust or contaminating optical/electronic components.

- Delamination/Cracking (Graphite): Brittle pads may crack under bending or vibration.

- Thermal Aging: Polymer matrix degradation at high temperatures reduces performance.

Recommended Certification and Testing Scheme

Practical test scheme suitable for most commercial and industrial applications:- Thermal Cycling (TC): −40°C → +125°C, 500–1000 cycles → Check for delamination due to CTE mismatch.

- Damp Heat (85/85): 85°C / 85% RH, 1000 hours → Check for moisture ingress/corrosion.

- Compression Set: 70–120°C, 1000 hours → Measure height loss.

- Vibration/Shock: According to product specifications → Check for mechanical fixation and fracture.

- Acceptance Criteria: ΔR″ or ΔT < 10%, and no significant delamination or contamination.

Mitigation Strategies

- Use silicone-free pads where outgassing could damage optical components.

- For long-life applications, select materials with low compression set.

- In high-vibration environments, design mechanical fixation devices (clips, adhesives).

- Pre-bake components before final assembly to remove weakly bound volatiles.

Frequently Asked Questions

Q: What are thermal gap pads used for?A: They are used to fill variable gaps between heat sources and heat sinks, providing a thermal pathway while typically also offering electrical insulation and mechanical flexibility.

Q: Can I reuse thermal gap pads?

A: Generally, no. Once compressed, the polymer chains relax (compression set), and the pad rarely returns to its original thickness. Reusing may lead to poor contact and air gaps.

Q: How do I choose the correct thermal gap pad thickness?

A: Measure the nominal gap and select an appropriate nominal pad thickness to achieve the desired compression percentage (typically 30-50%). Use the following formula: Nominal pad thickness ≈ Gap / (1 − Compression rate).

Q: How long do thermal gap pads last?

A: The lifespan depends on the material and environment. In demanding applications, periodic performance verification is required; if compression set or temperature drift exceeds specifications (e.g., >5°C), an investigation should be conducted.

Q: Can I cut thermal gap pads to the required size?

A: Yes – many pads are supplied in sheet form and can be manually cut using die-cutting or scoring. For high-volume production, it is best to use die-cut preforms to avoid edge fraying and debris.

Q: Do I need to worry about grease bleed-out?

A: If you have optical components or sensitive contacts, you do need to worry – low-bleed, silicone-free thermal gap pads should be selected.

Q: Thermal gap pads vs. thermal paste: which is better?

A: This depends on the gap size. For very small gaps (<0.1 mm), thermal paste performs better due to the extremely thin bond line thickness. For larger gaps (>0.5 mm), thermal gap pads are more advantageous because they are easy to install and provide electrical insulation.

Q: Can I stack thermal gap pads to fill larger gaps?

A: This is not recommended. The interface between two pads introduces new contact resistance, which significantly reduces performance. It is best to purchase a single pad of the appropriate thickness.

Thermal gap pads may seem simple, but they play a crucial role in thermal performance and product reliability. Choosing the right gap pad is key to balancing various physical parameters to suit different application scenarios. With careful selection, the appropriate thermal gap pad can effectively extend product life, improve efficiency, and prevent product failure.

At Sheen Technology, we offer comprehensive thermal interface solutions designed to meet the most demanding requirements. Visit our website or contact our technical support team to learn how Sheen Technology's thermal interface materials can enhance your product's thermal management capabilities.

English

English

usheenthermal

usheenthermal