Case Study: How Switching to a Carbon Fiber Thermal Pad Increased Heat Pipe Testing Efficiency

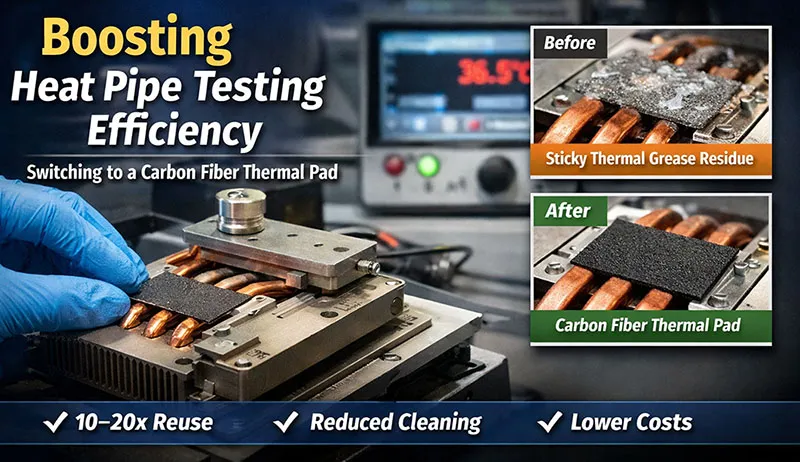

A single sticky thermal pad nearly shut down a production line — until a Carbon Fiber Thermal Pad saved the day. This case study explores how a leading electronics manufacturer overcame severe efficiency losses by switching from messy silicone pads to a high-durability Carbon Fiber Thermal Pad.

Background & Customer Pain Points in Heat Pipe Testing

The customer in this case study is a specialized manufacturer of high-performance heat pipes used in server cooling modules. Their reputation depends on 100% thermal verification of every unit leaving the factory.Testbench Workflow and Constraints

The customer's testing protocol involves devices under test are mounted to heat pipes, a TIM is applied, the bench runs a thermal cycle, then the DUT is removed for the next unit.Goals: continuous testing, minimal bench downtime, repeatable, consistent thermal contact.

Problems with Silicone Thermal Pads and Thermal Grease

Initially, the engineering team attempted to use standard 0.3mm and 0.5mm silicone thermal pads to mimic the performance of thermal grease without the mess. However, the results were disastrous for efficiency.- Residue: The silicone pads "bled" oil and adhered to the copper heat pipes under heat and pressure.

- Cleaning: Operators had to manually clean the heating block and the heat pipe with alcohol after every single test.

- Durability: The standard pads suffered from permanent compression set (refusing to rebound) after just one use, making them single-use consumables.

Customer KPIs at Risk

The friction caused by the interface material put several Key Performance Indicators (KPIs) at risk:- Throughput (units/day) and cycle tim

- Labor cost (operator-hours per unit)

- Consumable cost and testbench availability

- Data consistency (repeatable Rth/ΔT measurements)

The Challenge: Why Traditional Materials Failed in Stability Testing

The "Sticky" Situation: Residue and Cleaning Downtime

Standard silicone pads are inherently tacky. While this helps them stick to a heatsink in a permanent assembly, it is a nightmare for temporary testing. In this situation, thermal silicone pads or thermal grease leave residue, leading to poor contact. This requires cleaning the heat pipe and test bench after each test, thus interrupting continuous testing.The Labor Trap: Two Operators for One Job

To keep the line moving, the manufacturer had to deploy a second operator just to manage the mess. This doubled the labor cost per unit tested. The engineering manager realized that the "cheaper" silicone pad was actually the most expensive component in their process due to the operational drag it created.The Solution: Implementing the CSF20 Carbon Fiber Thermal Pad

After analyzing the failure of silicone, we recommended switching to the Carbon Fiber Thermal Pad, specifically engineered for testing environments.

Why Carbon Fiber? Material Science vs Silicone

CSF20 carbon fiber thermal pad engineered:- High through-plane thermal conductivity (15 ~45 W/m·K class in product family).

- High rebound (high-rebound formulation) to recover shape after compression.

- Low residue/bleed — it does not adhere to heat pipes like grease or low-rebound silicone pads.

Solving the Rebound Problem

Where 0.3/0.5 mm silicone pads failed after one use, CSF20 maintained structural integrity and contact across multiple cycles — the customer observed 10–20 reuses before performance deterioration, enabling batch testing without bench cleaning between each run.Overcoming price skepticism

Although unit price is higher than a disposable silicone pad or tube of grease, the reuse factor and reduced labor make total cost per test considerably lower. The customer’s pilot demonstrated a clear break-even when reuse exceeded a few cycles.The Results: Efficiency Gains with Carbon Fiber Thermal Pads

The pilot test results were immediate and transformative.From Single-Use to 20 Cycles

The durability test proved that a single piece of CSF20 could be reused for 10 to 20 test cycles before showing signs of thermal degradation. This instantly reduced the consumption of interface materials by 90-95%.Operational Transformation

The impact on the workflow was even more profound:- Zero Cleaning: Because the carbon fiber material left no residue, the cleaning step was eliminated entirely.

- One Operator: The second operator, previously dedicated to cleaning, was reassigned to another line.

- Continuous Flow: The test bench could run continuously, doubling the daily output capacity.

Total Cost of Ownership (TCO) Analysis

When the customer analyzed the numbers, the "expensive" pad was the clear winner.- Silicone Scenario: Low material cost + High labor cost + Low throughput = High TCO.

- Carbon Fiber Scenario: Higher material cost + Low labor cost + High throughput = Lowest TCO.

Lessons Learned, Best Practices & Recommendations for Other Heat Pipe Test Labs

Key Operational Takeaways

The test duration needs to remain constant, so the main factors affecting test efficiency here are the setup and disassembly times. By choosing reusable carbon fiber thermal pads, test efficiency is significantly improved.To achieve reusability through quality control and process improvements, and to reach more than 20 cycles of use, you must adhere to the material's performance limitations:

- Compression Limits: Do not over-compress. We recommend limiting compression to 15-20%. Over-compression can crush the carbon fibers and reduce the rebound capability.

- Visual Inspection: Train operators to look for "fiber bloom" or cracking on the pad edges. This indicates the pad is nearing its end of life and needs replacement to maintain measurement accuracy.

Procurement & Supplier Collaboration Tips

Applicability to Other Industries and Test Types

- IGBT Power Module Burn-in: Where residue on the baseplate is unacceptable.

- CPU/GPU Testing: Where high clamping pressure is available, and high wattage (W) must be dissipated quickly.

- Optical Transceiver Testing:Where cleanliness in the test fixture is paramount.

Frequently Asked Questions

Q: Is the Carbon Fiber Thermal Pad electrically conductive?A: Yes. Because it contains carbon fibers, the material is electrically conductive. It is ideal for heat pipes and metal chassis but should not bridge exposed electrical contacts or pins.

Q: Why does the Carbon Fiber Thermal Pad feel stiffer than silicone?

A: The stiffness comes from the vertical fiber alignment and the polymer matrix designed for rebound. This stiffness is actually an advantage in testing, as it prevents the pad from deforming or oozing out under high pressure.

Q: How many times can a Carbon Fiber Thermal Pad be reused?

A: In this case, the CSF20 was reused 10–20 times with stable performance; actual reuse depends on gap, pressure, and handling.

Q: Will it damage heat pipes?

A: No — carbon fiber pads leave minimal residue and do not adhere like thermal grease.

Q: Is switching cost-effective?

A: Yes when reuse and reduced labor lower the total cost per test; evaluate with a short pilot and simple TCO calc.

By switching to the CSF20 carbon fiber thermal pad solution provided by Sheen Technology, this customer's heat pipe testing process underwent a dramatic transformation, shifting from an inefficient, labor-intensive process to an efficient, single-person operation, while maintaining stable thermal performance and reducing the cost per test.

If your laboratory uses thermal grease or low-rebound silicone pads and is experiencing difficulties with cleaning or testing efficiency, contact us today for a sample and experience our high-rebound CSF20 thermal pads.

English

English

usheenthermal

usheenthermal