7 Crucial Thermal Pads Benefits for Maximizing Electronic Lifespan

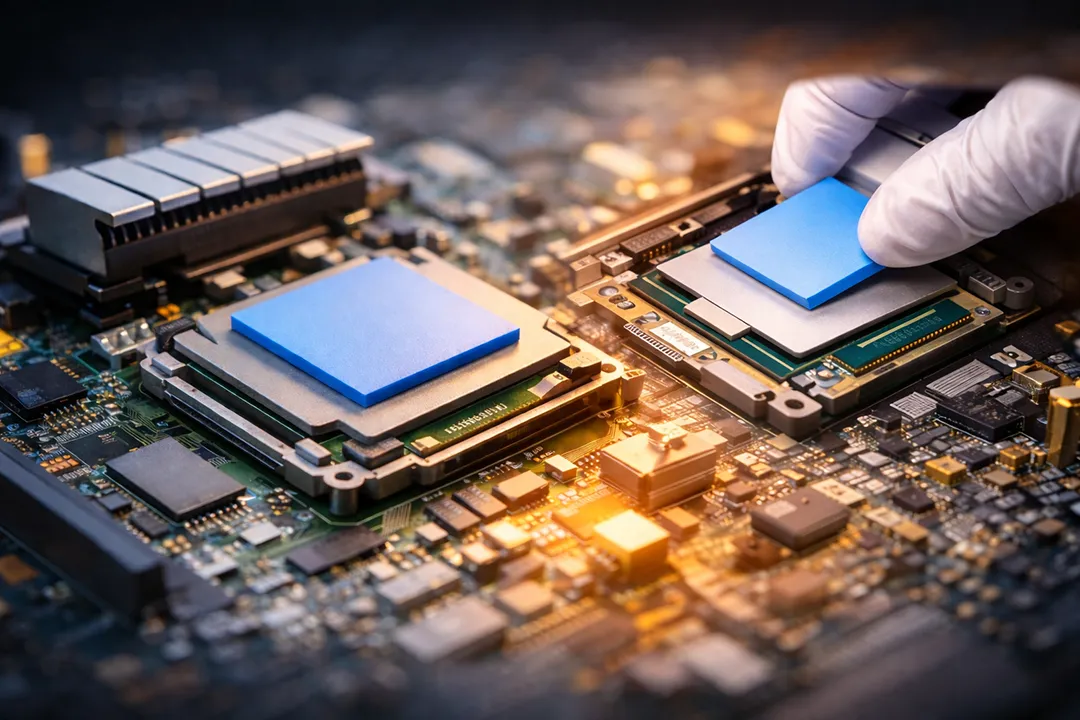

Heat is the greatest enemy in electronic products, and thermal interface materials are the key components for solving thermal issues. The right thermal material can efficiently conduct heat, ensuring stable operation of electronic devices.This article will focus on the core advantages of thermal pads and their specific performance in applications to explain why thermal pads are the critical components for addressing thermal challenges within thermal interface materials.

Understanding Silicone Thermal Conductivity and Material Stability

At the heart of most high-performance pads is silicone thermal conductivity. The core of most high-performance thermal pads is silicone thermal material. Silicone is chosen as the base polymer due to its following characteristics:- Thermal stability

- Sustained heat transfer

- Chemical inertness

Exploring Industrial Thermal Insulator Pads Applications

.webp)

While "thermal" implies heat, many thermal insulator pads applications are actually driven by the need for electrical safety. In many circuits, you need to move heat away from a component that is also carrying a high voltage.

- Dielectric Strength: Most thermal pads act as an electrical insulator. This is vital in Power Supply Units (PSUs) where a MOSFET might be bolted to a metal heatsink. The thermal pad conducts heat but blocks the flow of electrical current.

- Automotive and Electric Vehicle Battery Packs: Electric vehicle batteries are subjected to continuous vibrations and varying temperature fluctuations during use. A thermal gel or pad is used here because it cushions the battery cells while managing the massive heat load generated during fast charging.

.webp)

- LED Signage: Large-scale LED displays generate significant heat. Using pads instead of paste ensures that even if the display is mounted vertically, the cooling material won't "drip" or migrate due to gravity.

The 7 Core Benefits of Thermal Pads

Why exactly do engineers favor pads over other materials? Here is the breakdown:- Superior Gap Filling: Components on a circuit board are rarely the same height. Thermal pads come in various thicknesses (0.5mm to 10mm+) to bridge these uneven gaps perfectly.

- No "Pump-Out" Effect: Thermal paste is a semi-liquid. As a chip heats and cools, it expands and contracts, literally "pumping" the paste out from the center. Thermal pads, being solid materials, possess excellent flexibility and compressibility and are not affected by this phenomenon.

- Vibration damping and cushioning: In industrial machinery, prolonged use in a vibrating environment can lead to mechanical wear and tear. The soft nature of a thermal pad acts as a shock absorber for sensitive chips.

- Manufacturing Consistency: When you work with a thermal pad manufacturer, you get a product that is die-cut to the exact shape of your component. This eliminates the "human error" of applying too much or too little paste.

- Clean and Easy Installation: There are no messy syringes or solvents required. Installation is a simple "peel and stick" process, which significantly speeds up assembly lines.

- Aging Resistance: Solid thermal pads maintain elasticity and interface contact even under prolonged pressure due to their excellent compressibility and flexibility.

- Serviceability: Thermal pads can be die-cut into any shape per customer requirements and used directly during application. For equipment warranty repairs, the thermal pad can be completely removed without requiring chemical cleaning of the circuit board.

Why do engineers choose to partner with professional thermal pad manufacturers?

Some manufacturers excel at designing quality products, while others specialize in large-scale production. Therefore, selecting a professional thermal pad manufacturer not only ensures consistency between product design and mass production but also delivers the following advantages:- Custom Shore Hardness: You can request "ultra-soft" pads for fragile components or "high-modulus" pads for high-pressure applications.

- Customized Base Materials: To meet diverse customer requirements, professional thermal pad manufacturers offer various reinforced base materials. These include adding fillers such as PI film, fiberglass, or boron nitride to enhance the thermal pad's cut resistance and performance advantages.

- Custom Die-Cutting: To enable thermal pads to effectively fill complex gaps between heat sinks and electronic components, professional manufacturers can die-cut any shape according to customer specifications, ensuring the pad perfectly conforms to interface voids.

People Also Ask

Q: How long do thermal pads last?A: In most consumer and industrial applications, a high-quality silicone thermal pad will last between 5 and 10 years. They usually outlast the functional life of the electronic device itself.

Q: Are thermal pads better than thermal paste?

A: For "gap filling" (where the heatsink doesn't touch the chip perfectly) and long-term reliability, pads are better. For high-performance CPU overclocking where the gap is microscopic, paste may offer slightly lower temperatures initially.

Q: Can thermal pads be reused?

A: Generally, if the seal is damaged, it is best to replace the thermal pad with a new one. However, if the thermal pad is not torn and remains clean, it can sometimes be reused in non-critical applications.

Q: How thick should a thermal pad be?

A: Choose a close-fit thickness (0.5–2.0 mm common). Measure component planarity and allow slight compression (10–30%) for best contact.

Q: Can thermal pads be used in automotive electronics?

A: Yes — pick automotive-grade pads rated for temperature cycling and required certifications.

Q: Can thermal pads be stacked?

A: No, as this creates air gaps; it's best to purchase pads of appropriate thickness directly from the manufacturer.

Q: Do thermal pads expire?

A: It's advisable to check their shelf life before use, which is usually 1-2 years.

The advantages of thermal pads we've explored—from mechanical stability to electrical insulation—prove that heat dissipation is far more than just numbers on a thermometer. It's about ensuring your equipment operates as efficiently in its fifth year as it did on day one. By eliminating risks of drying out, pump leaks, and short circuits, thermal pads remain the gold standard for reliable engineering design.

Ready to safeguard your designs? Don't leave thermal management to chance. Contact our engineering team today for technical consultation, or request a complimentary sample kit of high-performance silicone pads to find the perfect solution for your next project.

English

English

usheenthermal

usheenthermal