Product Description

◆ High compressibility and excellent resilience for effective shock absorption, providing robust protection for devices.

◆ Available in a wide range of thicknesses, with uniform foaming that makes it easy to cut and process.

◆ Low stress relaxation properties help reduce maintenance costs associated with material failure.

◆ Ultra-soft characteristics offer protective seals with low closure forces to accommodate tolerances.

◆ Flame resistance rated at UL94 V-0 , enhancing safety standards.

◆ Resistant to UV, ozone, and extreme temperatures, ensuring long-term stability.

【Applications】

◆ Electric Vehicles (EV)◆ Battery packs

◆ Lighting and HVAC equipment

◆ Electrical control cabinets

◆ Electrical components

◆ Insulation systems

Properties

| Properties | SA700-200 | SA700-260 | SA700-300 | SA700-350 | SA700-400 | Test Method |

|---|---|---|---|---|---|---|

| Color | White, Gray, Black | Gray, Black | Gray, Black, Red | Gray, Black | Gray, Black | Visual |

| Density (kg/m3) | 200 | 260 | 300 | 350 | 400 | ASTM D1056 |

| Thickness (mm) | 1.6~20.0 (±10%) | 1.2~20.0 (±10%) | 1.2~20.0 (±10%) | 0.6~20.0 (±10%) | 1.0~12.0 (±10%) | ASTM D374 |

| Compression Set (@50%, 100℃) | <5% | <5% | <5% | <5% | <5% | ASTM D1056 |

| Compression Force Deflection (kPa) | 7 | 10 | 30 | 50 | 80 | ASTM D1056 |

| Water Absorption | <5% | <5% | <5% | <5% | <5% | ASTM D1056 |

| Tensile Strength (kPa) | 100 | 120 | 200 | 280 | 350 | ASTM D412 |

| Elongation | 60 | 70 | 60 | 90 | 80 | ASTM D412 |

| Thermal Conductivity (W/m·K) | 0.05 | 0.05 | 0.05 | 0.071 | 0.064 | ASTM E1461 |

| Volume Resistivity (Ω·cm) | >1014 | >1014 | >1014 | >1013 | >1013 | ASTM D257 |

| Flame Rating | V-0 | V-0 | V-0 | V-0 | V-0 | UL 94 |

| Operating Temp. (℃) | -55~200 | -55~200 | -55~200 | -55~200 | -55~200 | - |

【Product Specifications】

According to Customers’Requirements【Storage & Transportation】

Store in a well-ventilated, cool, and dry place, away from open flames.This product is non-toxic and should be stored and transported as a non-hazardous material.

【Packaging】

Customized packaging according to customer requirements.【Shelf Life】

10 yearsAbout Us

◆ Founded: 2008

◆ Team: 110 employees

◆ Facility: 5,000㎡

◆ Focus: R&D and production of functional materials

◆ Strengths: Efficient, collaborative team

◆ Achievements: Key supplier to leading global manufacturers

◆ Applications: Telecom, Automotive, Medical, Computing, Industrial , Military

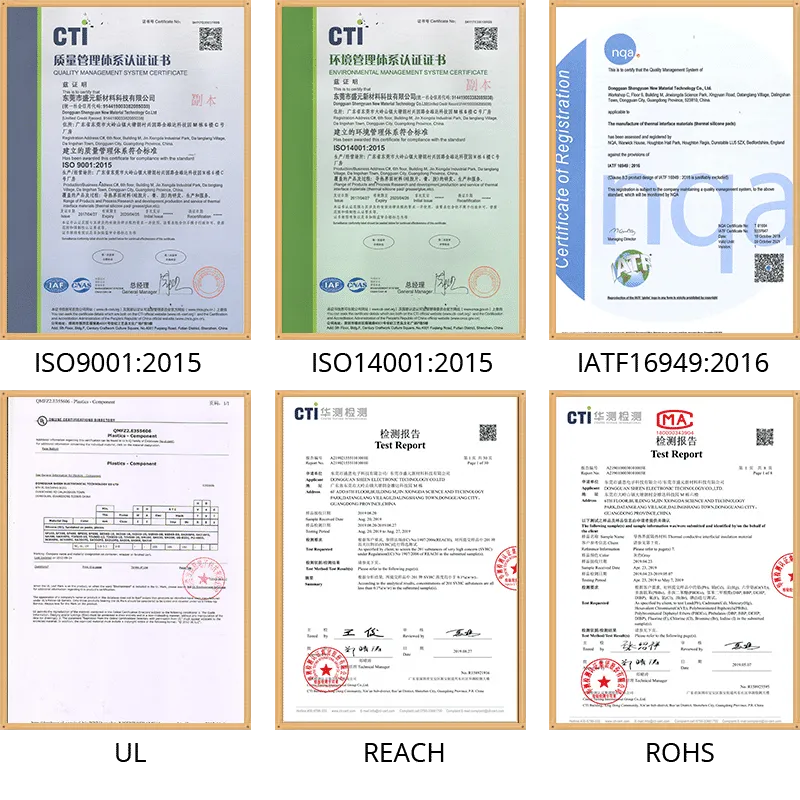

◆ Certifications: ISO9001:2015, ISO14001:2015, IATF16949:2016

Partners

Certifications

English

English

usheenthermal

usheenthermal

.webp)

.webp)

.webp)