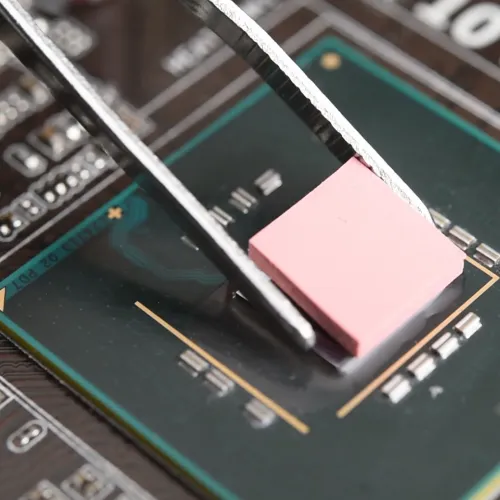

Silicon - free thermal pad used in PCB, heat sink, electronic module, etc

Silicon - free thermal pads are highly suitable for use in PCBs, especially in environments where silicon contamination is a critical concern, such as in precision electronic assemblies or optical equipment. These pads are placed between heat - generating components on the PCB, like power transistors and voltage regulators, and the board's heat - spreading layers or attached heat sinks. Unlike silicon - based alternatives, they do not release silicone oils that can interfere with solderability or cause issues with optical surfaces. At operating temperatures, silicon - free thermal pads maintain a consistent thermal conductivity, effectively transferring heat from the components to the heat - dissipating structures. They also exhibit good mechanical compliance, conforming to the irregularities of component surfaces and PCB traces to minimize thermal resistance. For example, in automotive PCB assemblies where reliability under harsh conditions is paramount, silicon - free thermal pads ensure efficient heat management without compromising the integrity of the board's electrical connections.

![]()

When integrated with heat sinks, silicon - free thermal pads serve as an excellent interface material, particularly in applications where silicon contamination could damage sensitive components or affect system performance, such as in aerospace and medical devices. They are placed between the heat - generating component (e.g., a laser diode or a medical imaging chip) and the heat sink's base. These pads offer stable thermal performance across a wide temperature range, ensuring that heat is efficiently conducted from the component to the heat sink's fins for dissipation. Their silicon - free composition prevents the formation of insulating layers that might otherwise form due to silicone degradation, maintaining long - term heat transfer efficiency. Additionally, they provide good adhesion to both the component and heat sink surfaces, reducing the risk of interface separation during thermal cycling. In high - precision medical equipment heat sinks, for instance, silicon - free thermal pads ensure that critical components remain at optimal temperatures without introducing contaminants that could compromise the device's sterility or functionality.

![]()

Silicon - free thermal pads play a vital role in electronic modules that house sensitive components prone to silicon - related issues, such as radio frequency (RF) modules and sensor modules. They are installed between the module's internal heat sources, like RF amplifiers and MEMS sensors, and the module's casing or internal heat - dissipating structures. The absence of silicon in these pads eliminates the risk of signal interference that can occur with silicon - based materials, which can act as dielectrics and disrupt RF signals. At the same time, they provide effective thermal conduction, drawing heat away from the sensitive components to keep their temperatures within acceptable limits. Silicon - free thermal pads also offer good chemical resistance, making them suitable for modules exposed to various industrial fluids or cleaning agents. In RF communication modules, for example, these pads ensure that the heat generated by high - power transmitters is dissipated efficiently without degrading the module's signal transmission quality, thus maintaining reliable communication performance.

English

English

usheenthermal

usheenthermal