Thermal phase change sheet used in electronic module, PCB, heat sink, etc

Electronic modules house multiple heat - generating components such as microprocessors, memory chips, and DC/DC converters. Thermal phase change sheets play a crucial role here. At room temperature, these sheets are solid and easy to install between the heat - generating elements and the module's heat - dissipating structure. When the module operates and the temperature rises to the phase - change temperature of the sheet (usually around 45 - 60 °C), the sheet softens. It then fills the microscopic gaps between the components and the heat - dissipating surface, reducing the thermal resistance. This enables more efficient heat transfer from the components to the heat - dissipating part of the module. As a result, the temperature of the sensitive electronic components is kept within a safe operating range, enhancing the overall reliability and performance of the electronic module. For example, in high - performance computing modules, where processors generate a significant amount of heat, thermal phase change sheets ensure that the heat is effectively removed, preventing overheating - related issues like system slowdowns or crashes.

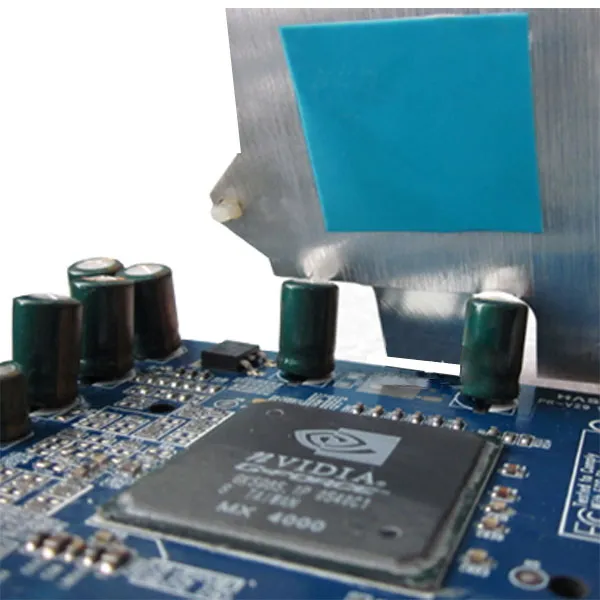

PCBs are integral to electronic devices, with numerous components soldered onto them. Heat generation on PCBs can be a major concern as it can affect the functionality of the components and the lifespan of the board. Thermal phase change sheets are applied between the heat - producing components on the PCB, such as integrated circuits, and the heat - sink or the metal chassis (if used for heat dissipation). As the PCB operates and heats up, the phase change sheets transition from a solid to a soft, semi - fluid state. This allows them to conform to the uneven surfaces of the components and the heat - dissipating structure, eliminating air gaps. Air gaps are known to have high thermal resistance, and by replacing them with the phase - changed sheet material, the heat transfer efficiency from the components to the heat - sink is significantly improved. In applications like LED driver PCBs, where LEDs generate substantial heat, thermal phase change sheets help in maintaining the optimal operating temperature of the LEDs, thus ensuring consistent light output and longer LED lifespan.

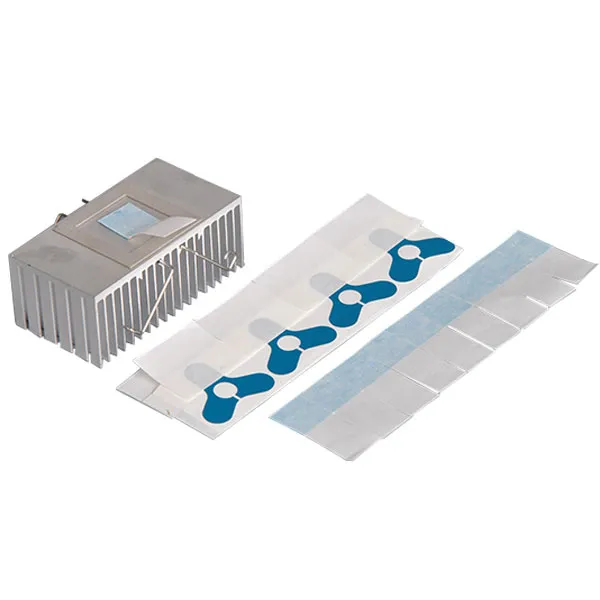

Heat sinks are designed to dissipate heat away from heat - generating components. Thermal phase change sheets are used as an interface material between the component and the heat sink. When installed, at normal temperatures, the sheet provides a stable and easy - to - handle connection. Once the component starts heating up, the phase change sheet softens. This softening enables it to closely adhere to both the component's surface and the heat sink's surface, maximizing the contact area for heat transfer. By filling the small voids and irregularities on the surfaces, the sheet reduces the thermal resistance at the interface. For instance, in computer CPU heat sinks, the thermal phase change sheet allows the heat generated by the CPU to be quickly transferred to the heat sink's fins. The fins then dissipate this heat into the surrounding air. This process ensures that the CPU remains cool during operation, preventing performance degradation due to overheating and enhancing the overall stability of the computer system.

English

English

usheenthermal

usheenthermal