Thermal pad applied in PCB, heat sink, LED lamp, mobile phone,etc

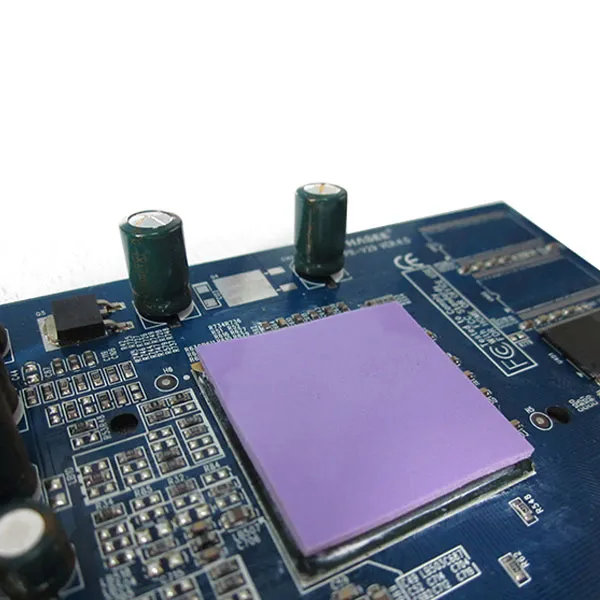

Thermal pads are widely used in PCBs to bridge heat-generating components (like transistors and chips) and heat-dissipating structures. They conform to surface irregularities, ensuring tight contact to minimize thermal resistance. With stable thermal conductivity, they efficiently transfer heat, preventing overheating in compact PCB layouts. Their pre-cut shapes fit easily into assembly processes, simplifying installation.

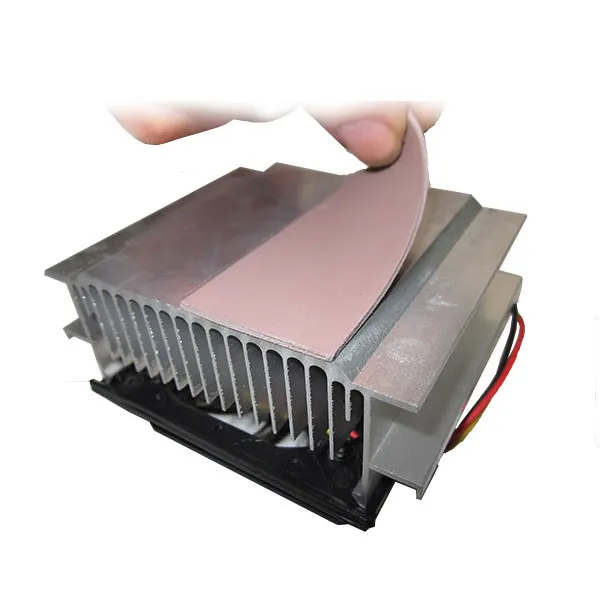

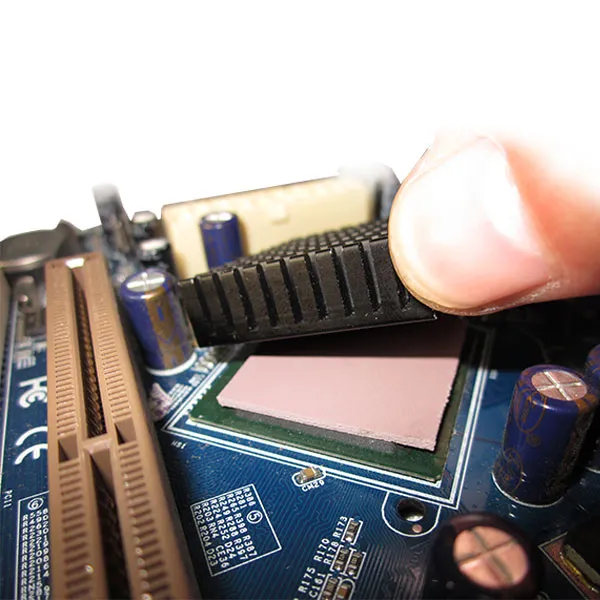

In heat sinks, thermal pads act as a reliable interface between the heat sink and heat sources (e.g., CPUs). They fill microscopic gaps between surfaces, enhancing heat transfer from the source to the heat sink. Available in various thicknesses, they accommodate different spacing needs, maintaining consistent thermal performance even under thermal expansion.

Thermal pads in LED lamps connect LEDs to heat sinks, crucial for managing the heat LEDs emit. They provide a low-resistance path for heat transfer, keeping LEDs at optimal temperatures to preserve brightness and lifespan. Their flexibility adapts to LED and heat sink surfaces, ensuring long-term thermal contact without degradation.

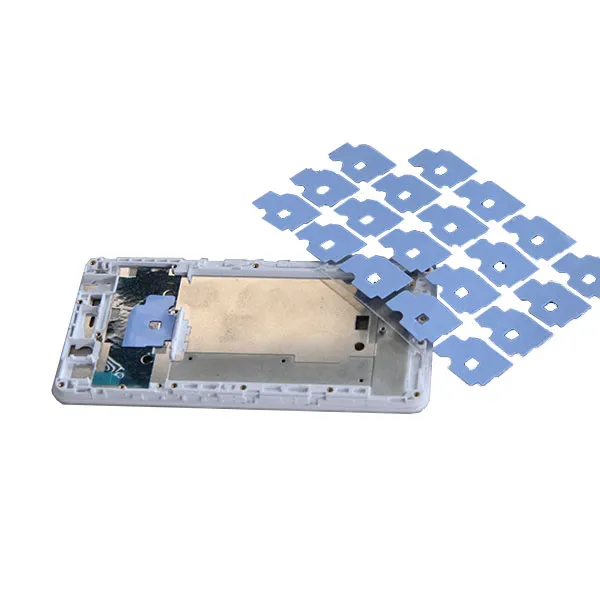

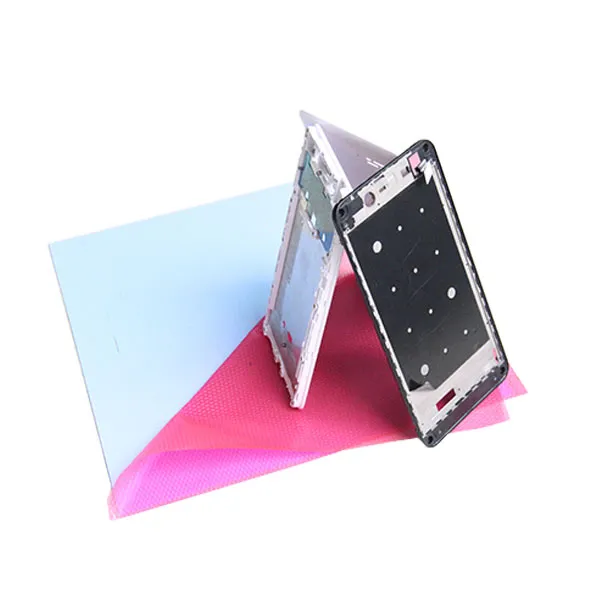

In mobile phones, thermal pads fit into tight spaces between components (such as processors and batteries) and the device's chassis. They efficiently spread heat from high-power parts, preventing hotspots. Thin and lightweight, they don't add bulk, suiting slim phone designs, while their conformability ensures good contact despite constant use vibrations.

English

English

usheenthermal

usheenthermal